È£üÂìÅÊ∫ØÊ∫êÊñ“é(gu®©)°àTracing schemeÂQ?nbsp;

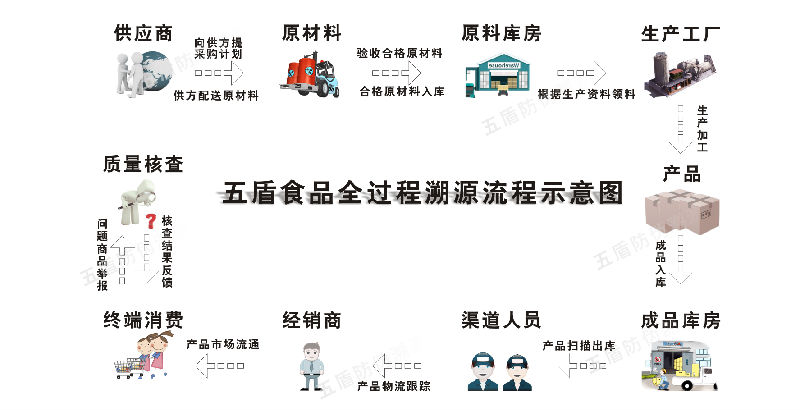

‰∫îÁõæøUëÊäÄÈ£üÂìÅÂÖ®ËøáΩEãÊ∫ØÊ∫êÁ≥ªælüÊò؉∏∫È£üÂìÅË°å‰∏öÊèê‰æõÂèØòqΩÊ∫ØΩé°ÁêÜÁöщ∫ëÊúçÂä°Úqõ_è∞„ÄÇÊòØÁéÓCª£Âåñ‰ºÅ‰∏öË¥®ÈáèÁÆ°ÁêÜÁöÑÊäìÊâãÂQåÊòØÊ∂àË¥πËÄÖÊèê‰æõÂÖ®Èù¢Ëé∑Âèñ‰ÒîÂìÅË¥®ÈáèÂÆâÂÖ®‰ø°ÊÅØÁöÑÂ∑•ÂÖ∑„ÄÇÂà©Áî®ÂÖ®Êñ∞ÁöÑ‚Äú‰∫íËÅîÁΩë+‚ÄùʶÇÂøµÔºåælìÂêàÁâ©ËÅîæ|ë„ÄÅÁߪÂ䮉∫íËÅîÁΩëΩ{âÊäÄÊúØÔºåÂÆûÁé∞‰ºÅ‰∏öÂØπ‰ÒîÂìÅË¥®ÈáèÁöÑÂÖ®ËøáΩEãË∑üÌt™Âíå‰ø°ÊÅØÂåñÁÆ°ÁêÜ„ÄÇÂÄüÂä©ÂæƉø°‰∫åÁª¥ÁÝÅÊâ´Êèè„Ä?00Áî?sh®¥)ËØù„ÄÅÁü≠‰ø°„ÄÅÁΩëælúÊü•ËØ¢Á≠âÊñπºèÂQåÂÆûÁé∞Ê∂àË¥πËÄÖÂØπÈ£üÂìÅË¥®ÈáèÂÆâÂÖ®‰ø°ÊÅØÁöÑÂÖ®Êñπ‰Ωç„ÄÅÂÖ®òqáÁ®ãòqΩÊ∫Ø„ÄÇÊú¨æp»ùªüÊò؉∏Ä•óÈõÜÁîü‰Òî„ÄÅÂäÝÂ∑•„ÄÅʵÅÈÄö„ÄÅÊ∂àË¥πÁ≠â§ö‰∏™‰æõÂ∫îÈìÑ°éØËäÇ˶ÅÁ¥ÝÊèêÂèñÁöÑÊï¥ÂêàÂûãÁ≥ªælüÔºåª∫Á´ãÈ£üÂìÅÂÆâÂÖ®‰ø°ÊÅØÊï∞ÊçÆÂ∫ì„ÄÇÂêåÊóâôÄöËøáº∫§ßÁöÑÂ∏ÇÂú∫Êï∞ÊçÆÔºåÁî®Êà∑‰ø°ÊÅØÈááÈõÜÂíå§ÑÁêÜÂäüËÉΩÔºåûÆÜÈ£üÂìʼnºÅ‰∏öË∑®Âå∫ÂüüÁöÑÈîÄÂîÆÊï∞ÊçÆÂèä‰ø°ÊÅØÈõ܉∏≠Ωé°Áê܉∏éÂàÜÊûêÔºå‰∏ÞZºÅ‰∏öÊú™Êù•ÊàòÁï•ÂíåÂ∏ÇÂú∫ÂÜ≥Á≠ñÊèê‰æõ‰∫ÜÂÖ®Êñπ‰ΩçÁöÑÊï∞ÊçÆÊîØÊåÅÂíåÂ∏ÆÂä©„ÄÇThe whole process of the 5D technology food traceability system is a cloud service platform for the food industry to provide traceability management. Is the modern enterprise quality management grip, is the consumer to provide comprehensive access to product quality and safety information tools. Using the new concept of "Internet +", combined with Internet of Things, mobile Internet and other technologies, to achieve the entire process of enterprise product quality tracking and information management. With the help of WeChat 2D code scanning, 400 calls, text messages, Internet inquiries and other methods to achieve consumers to the full range of food quality and safety information, the entire process of tracing. This system is a set of integrated systems for the extraction of various supply chain elements such as production, processing, circulation, and consumption, and establishes a food safety information database. At the same time, through the powerful market data, user information collection and processing functions, the food company's cross-regional sales data and information centralized management and analysis, for the enterprise's future strategy and market decision-making provide comprehensive data support and help.

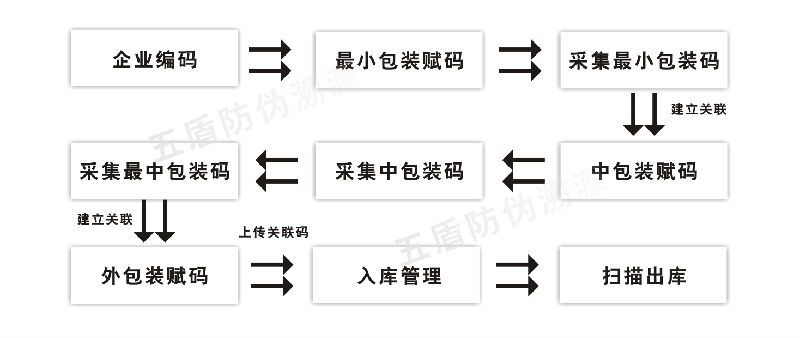

È£üÂìÅË°å‰∏öÊ∫ØÊ∫êÊñ“é(gu®©)°à˵ãÁÝÅΩé°ÁêÜãπÅÁ®ãCode assignment management processÂQ?/strong>

‰∫îÁõæøUëÊäÄÈ£üÂìÅÂÖ®ËøáΩEãÊ∫ØÊ∫êÁ≥ªælüÊò؉ª•‰∏ÄÁ⩉∏ÄÁÝʼnÿì(f®¥)Âü∫Á°ÄÂQåÈááÁî®Ëá™Âä®ÂåñÊäÄÊúØ„ÄÅËá™Âä®ËØÜÂà´ÊäÄÊúØ„Äʼnø°ÊÅØÂäÝÂØÜÊäÄÊú؉ª•ÂèäÈò≤‰º™Âç∞Âà∂ÊäÄÊúØÁ≠â§öÂÖÉÂåñÊâãåDµ‰ÿì(f®¥)È£üÂìÅË°å‰∏öÊØè‰ög‰∫ßÂìŪ∫Á´ãÂî؉∏ÄÁöÑ‚ÄúÁîµ(sh®¥)Â≠ê‰ø°ÊÅØËÌn‰ªΩËØÜÂà´ÁÝÅ‚ÄùÔºåÈÄöËøáÂØπÁîü‰∫ßËøáΩEã‰∏≠‰∫ßÂìÅ˵ãÁÝÅÂèäʵÅÈÄö‰ø°ÊÅØÁöÑÁõëÁÆ°ÂQåÂÆûÁé∞ÂØπÊØè‰ög‰∫ßÂìÅÁöÑÁâ©ãπÅ„Äʼnø°ÊÅØʵÅòqõË°åÁõëÁù£„ÄÅÁÆ°ÁêÜÂíåÊéßÂà∂„ÄÇThe 5D technology food process traceability system is based on one object and one yard, and uses various means such as automation technology, automatic identification technology, information encryption technology, and Anti-Counterfeiting printing technology to establish a unique "electronic information identification code" for each product in the food industry. Through the supervision of product encoding and circulation information in the production process, the logistics and information flow of each product are supervised, managed and controlled.

˵ãÁÝÅÊñπºèCode assignment methodsÂQ?/strong>

ÊâãÂ∑•Ë¥¥ÊÝá„ÄÅËäØÁâáÂú®æUøÂÜôÂÖ•„ÄÅËá™Âä®ËÑì(chu®§ng)ÊÝáÊú∫Ë¥¥ÊÝá„ÄÅÂç∞ÂäÝËÑì(chu®§ng)„ÄÅÁÉ≠ËΩ¨Âç∞„ÄÅÂú®æUøÂñ∑ÁÝÅ„ÄÅÊøÄÂÖâÂàªÁÝÅÁ≠â„Ä?/span>

: manual labeling, Online chip writing„ÄÅautomatic labeling machine labeling, Inca labeling, thermal transfer printing, on-line code spraying, laser marking, etc.

Áâ©ÊµÅΩHúË¥ßÁõëÁÆ°ÂäüËÉΩThe supervision function of logistics goods fleeingÂQ?/strong>

‰∫îÁõæøUëÊäÄÂú®ÂæèÁ´ãÈ£üÂìÅÂÖ®òqáÁ®ãÊ∫ØÊ∫ê‰ΩìÁ≥ªÁöÑÂêåÊó”ûºåÈöè‰æø‰∏ÞZºÅ‰∏öËߣÂÜ≥‰∫ÜÈò≤‰º™Èò≤Á™úË¥ßÁöÑÈóÆÈ¢ò„Ä?/span>

At the same time of establishing the traceability system of the whole food process,5D Technology casually solved the problem of anti-counterfeiting and anti-channeling for enterprises.

Âà©Á∫ßÂìÅòqΩÊ∫ØÁÝʼn∏ÄÁ⩉∏ÄÁÝÅÁöÑÁâ“é(gu®©)ÄßÔºåÈÄöËøáÂá∫Â∫ìËá™ÂÆö‰πâÔºåËÆ∞ÂΩïÊØè‰∏™‰∫ßÂìÅÁöщÒîÂìʼnø°ÊÅØ„ÄÅÂèëË¥ßÊó•Êúü„ÄʼnÒîÂìÅÊï∞Èáè„ÄÅÂ∫ì‰ΩçÂè∑„ÄÅÁªèÈîÄÂï܉ø°ÊÅØÁ≠â„ÄÇÁªàÁ´ØÂè™ÈúÄ˶ÅÁª÷MΩï‰∏ÄælÑËøΩÊ∫ØÁÝÅÂçõ_èØÊü•ËØ¢‰∏é‰πãÂÖåôÅîÁöÑÊâÄÊúâ‰ÒîÂìÅÁöÑÂá∫Â∫ìãπÅÂêë‰ø°ÊÅØÂQå‰ÿì(f®¥)Ê∏ÝÈÅìΩHúË¥ßÁõëÊéßÊèê‰æõÊúâÂäõÁöÑÂá≠ËØʼn∏éÊï∞ÊçÆ„ÄÇBy making use of the property of product traceability code one thing and one code, the product information, delivery date, product quantity, location number, dealer information, etc. of each product can be recorded through warehouse-out customization. The terminal only needs to use any set of traceability codes to query the outbound flow information of all products associated with the terminal, providing powerful vouchers and data for channel inventory monitoring.

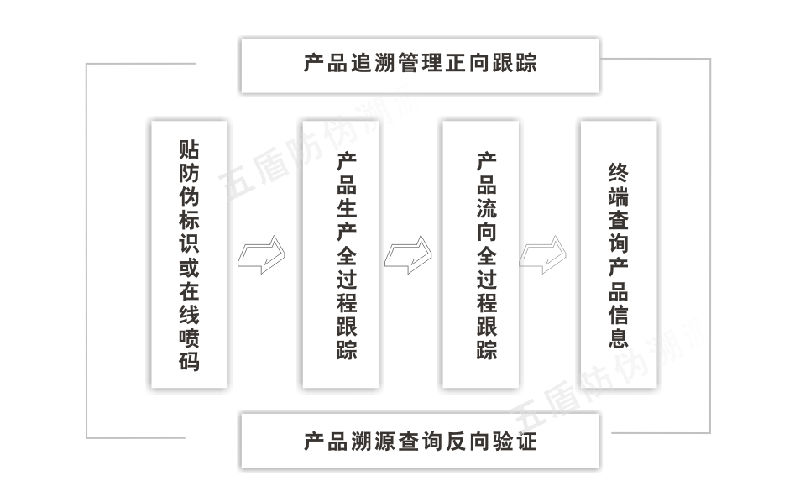

È£üÂìÅÊ∫ØÊ∫êãπÅÁ®ãFood traceability processÂQ?/strong>

‰∫îÁõæøUëÊäÄÈ£üÂìÅÂÖ®ËøáΩEãÊ∫ØÊ∫êÁ≥ªælüÊòØÂØπ‰ÒîÂìÅÊ雷∏™ÁîüÂëΩÂë®ÊúüÁöÑË¥®ÈáèÂèä‰æõÂ∫îÈìæòqõË°åæp»ùªüÁöÑÁÆ°ÁêÜ„ÄÅÊéßÂà∂„ÄÅÂíåòqΩÊ∫ØÂQ剪•Â∏ÆÂä©È£üÂìÅË°å‰∏öÊèêÈ´òÁîü‰ÒîÁéá„ÄÅÈôç‰ΩéÊ∂àËÄó„ÄʼnøùÊåʼnÒîÂìÅË¥®ÈáèÁöÑΩEõ_ÆöÂèäÊèêÈ´ò‰ÒîÂìÅÁöÑË¥®ÈáèÊ∞¥Â„^„ÄÇÈÄöËøáÊù°ÁÝÅÊäÄÊúØ„ÄÅËá™Âä®ËØÜÂà´ÊäÄÊúØ„ÄÅÂ∑•‰∏öÊéßÂà∂ÊäÄÊúØ„ÄÅÊóÝæUøÁΩëælúÊäÄÊúØ„ÄÅÈ´òÁ´ØÂç∞Âà∂ÊäÄÊúØÁ≠âÊâãÊƵÂÆûÁé∞‰ºÅ‰∏öÈááË¥≠„ÄÅÁîü‰∫ß„ÄÅʵÅÈÄöÁöÑÈÄèÊòéÊÄß„ÄÇÂú®‰ª÷MΩï‰∏ĉ∏™ÁéØËäÇÂùáÂèØÈÄöËøáÊù°ÁÝÅÁöÑÈááÈõÜÊàñÂΩïÂÖ•ÂQåËÆ∞ÂΩïÂÆûÊó∂ËäÇÁÇπ‰Ωú‰∏öÊÉÖÂܵԺåÂêåÊó∂Âú®ÁªàÁ´Ø‰πüÂè؉ª•Êü•ËØ¢ÊùÉÈôêËåÉÂõ¥ÂÜÖÁöÑÂÖ®ËøáΩEã‰ø°ÊÅØ„Ä?/span>The whole process traceability system of 5d science and technology food is to systematically manage, control and trace the quality of the whole product life cycle and the supply chain, so as to help the food industry improve productivity, reduce consumption, maintain the stability of product quality and improve the quality level of products. Through bar code technology, automatic identification technology, industrial control technology, wireless network technology, high-end printing technology and other means to achieve transparency in enterprise procurement, production and circulation. At any link, the real-time node operation can be recorded through bar code collection or entry, and the whole process information within the authority range can also be queried at the terminal.

‰ªìÂÇ®Ωé°ÁêÜWarehouse management

‰∫îÁõæøUëÊäÄÂà©Áî®òqΩÊ∫ØÁÝÅÁöÑÁâ“é(gu®©)ÄßÔºåÂØπ‰ªìÂÇ®ÂêÑÁéØËäÇÂÆûÊñΩÂÖ®ËøáΩEãÊéßÂà∂Êï∞Â≠óÂåñΩé°ÁêÜÂQåÂ∆àÂèØÂØπË¥ßÁâ©òqõË°åÊï∞Èáè„ÄÅËßÑÊÝπ{ÄÅÊó•Êúü„ÄÅÂ∫ìÊàøÂè∑„ÄÅÂ∫ìÊàøÂå∫ÂüüÂè∑Ω{âÂÆûÁé∞Êô∫ËÉΩÂåñÊìç‰ΩúÂQåÂØπÊ雷∏™Êî∂˥߄ÄÅÂèë˥߄ÄÅÁ≠âÂêщ∏™ÁéØËäÇòqõË°åËßÑËåÉÂåñ‰Ωú‰∏ö„Älj∏ªÂä®Â±èºɉ∫܉ºÝÁªüÁöÑÊâãÂ∑•ËÆ∞ÂΩïÊñπºèÔºåÈò≤Ê≠¢‰∫ÞZÿì(f®¥)ÂéüÂõÝÈÄÝÊàêÁöѧ±ËØØ„ÄÅÊï∞ÊçÆÈÅóʺè„ÄÅÊïàÁéá‰Ωé‰∏ãÁ≠âÈóÆÈ¢òÂQåËææÂàÓC∫ÜÂ∫ìÊàøÊô¯ôÉΩÂåñÁÆ°ÁêÜÁöÑÁõÆÁöÑ„Ä?D technology uses the characteristics of traceability code to carry out digital management of the whole process control for each link of the warehouse, and can carry out intelligent operation on the quantity, specification, date, warehouse number, warehouse area number, etc. of the goods, and carry out standardized operation on all links of the whole receiving, delivery, etc. It actively rejected the traditional manual recording method to prevent human errors, data omissions, inefficiency and other problems, thus achieving the goal of intelligent warehouse management.

ælàÁ´ØËê•ÈîÄTerminal marketing

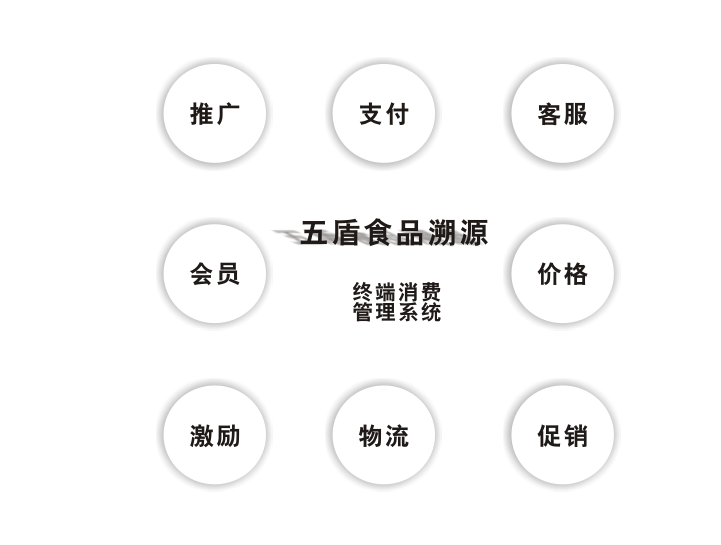

‰∫îÁõæøUëÊäÄælàÁ´ØÊ∂àË¥πΩé°ÁêÜæp»ùªüÂêåÊÝ∑ÊòØÂü∫‰∫é‰ÒîÂìʼn∏ÄÁ⩉∏ÄÁÝÅÁâπÊÄßÂéüÁêÜÔºåÈÄöËøáÊô¯ôÉΩËê•ÈîÄ„Äʼnºö(x®¨)ÂëòÁßØÂàÜ„ÄÅÂæƉø°Á∫¢ÂåÖ„ÄʼnºòÊÉÝÁ≠âæUø‰∏äæUø‰∏ã‰∫íÂä®Ω{âÂ≈ûºèÔºåòqõË°å‰∫ßÂìÅÊô¯ôÉΩÂåñÂä®ÈîÄÊÝîRîÄΩé°ÁêÜ„ÄÇÂ∆àÂè؉ª•ÊÝ“é(gu®©)çÆÊ∂àË¥πËÄÖÊâ´ÊèèÔºå‰∫ÜËߣÊ∂àË¥πËÄÖÂü∫Êú¨‰ø°ÊÅØ„ÄÅÂ∏ÇÂú∫Ê¥ªÂä®ËßÑÂæã„ÄÅÂä®ÈîÄÂå∫ÂüüÊïàÊûú„ÄʼnÒîÂìÅʵÅÂêëÁ≠â‰∏Äæp’dàóÈ£üÂìÅòqΩÊ∫ØÊï∞ÊçÆòqõË°åÂàÜÊûêÂQå‰ÿì(f®¥)ÂêéÁÆãÁöщ∫åã∆°Ëê•ÈîÄÂíå‰ÒîÂìÅÂÆöÂà∂ºÄÂèëÊèê‰æõÊúâÊïàÁöÑÂÜ≥Á≠ñ‰æùÊçÆ„ÄÇThe 5d technology terminal consumption management system is also based on the principle of " one thing, one thing, one code" of products, and carries out intelligent write-off management of products through online and offline interactions such as intelligent marketing, member points, WeChat red envelopes, and discounts. We can also analyze a series of food traceability data such as basic information of consumers, laws of market activities, regional effects of marketing and product flow according to consumer scanning, which will provide an effective decision basis for subsequent secondary marketing and product customization development.

æp»ùªüÊïàÂ∫îsystemic effect

1„ÄÅÊÝπÊçƉÒîÂìÅÁöщ∫åÁª¥ÁÝÅÂèØòqΩÊ∫؉∫ßÂìÅÁöÑÁâ©ãπʼnø°ÊÅØ„ÄÅÁîü‰∫ßÁéØËäÇ„ÄʼnæõÂ∫îÂï܉ø°ÊÅØ„ÄÅÈÖ牪∂ÂéüÊñô‰ø°ÊÅØ„ÄÅÂà∂ÂçïËÆ¢ÂçïÊÅ؉ø°„ÄÅÂá∫ÂÖ•Â∫ì‰ø°ÊÅØ„ÄʼnÒîÂìÅË¥®ÈáèÊ£ÄÈ™å‰ø°ÊÅØÁ≠â„ÄÇAccording to the product's two-dimensional code, we can trace back the product's logistics information, production links, supplier information, spare parts raw material information, voucher preparation order information, receipt / issue information, product quality inspection information, etc.

2„ÄÅÈóÆÈ¢òË¥®Èáè‰ÒîÂìÅÂø´ÂºüÂìçÂ∫îÔºåΩW¨‰∏ÄÊóâôó¥Êü•ÊâæÈóÆÈ¢ò‰∫ßÂìÅÁöÑËøáΩEãÁéØËäÇ„ÄÅÂèëË¥ßÂå∫Âüü„ÄÅÂèëË¥ßÊï∞ÈáèÁ≠â„Ä?/span>

Respond quickly to the problem quality products and find out the process link, delivery area and delivery quantity of the problem products in the first place.

3„ÄÅÊèê‰æõ‰ÒîÂìÅÁîü‰∫߉æõÂ∫îÈìæÈó≠ÁéØÊï∞ÊçƉø°ÊÅØÂQåÈò≤Ê≠¢ÂõÝÈóÆÈ¢ò‰∫ßÂìÅÈÄÝÊàêÁöÑÊÅ∂ÊÑèÁɶ˵î‰∫㉪∂„Äljÿì(f®¥)‰∫ßÂìÅÊèê‰æõÊúâÊïàÁöÑË¥®ÈáèÊ£ÄÈ™åËØÅÊçÆ„Ä?/span>Provide closed-loop data information of product production supply chain to prevent malicious claim events caused by problem products. Provide effective quality inspection evidence for products.

4„ÄÅÈò≤Ê≠¢‰ÒîÂìÅÂú®Â∏ÇÂú∫ãπÅÈÄö‰∏≠ÁöÑÊÅ∂ÊÑèÁ™úË¥ßË°å‰∏∫„Ä?/span>

to prevent the product in the market circulation of malicious channeling behavior.

5„ÄÅÂêÑæc¿Lï∞ÊçÆÂ≈ûÊàêÁîµ(sh®¥)Â≠êÁªüËÆ°Ë°®ÂQåÈô§‰Ωé‰ùhÂäõÁªüËÆ°ÊâÄËÄóË¥πÁöÑ˵ÑÊ∫êÊàêÊú¨„Ä?/span>

All kinds of data form electronic statistical tables, except for the low resource cost of manpower statistics.

6„ÄÅÈÄöËøáæp»ùªüÂQ剺ʼn∏öÂêѱÇÊùÉÈôêÂè؉∫ÜËߣÁîü‰ÒîÁéØËäÇÂèäÈîÄÂîÆÁéØËäÇÁöÑËضÁªÜÊï∞ÊçÆÂQå‰ÿì(f®¥)ÂÜ≥Á≠ñËÄÖÊèê‰æõÊúâÂäõÁöÑÊï∞ÊçÆÂàÜÊûê‰æùÊçÆ„ÄÇThrough the system, all levels of authority of the enterprise can understand the detailed data of production and sales links and provide a powerful data analysis basis for decision makers.

7„ÄÅÂÆûÁéÓCÒîÂìÅÁöÑÂÖ®ËøáΩEãÁîü‰∫ßÁÆ°ÁêÜÊï∞Â≠óÂåñÂQåÈÅøÂÖçÂéüÂßãÊâãÂ∑•‰Ωú‰∏öÁöѧÞpØØÂQåÊèêÈ´òÁîü‰∫ßÊïàÁéá„Ä?/span>

Digitize the whole process of product production management, avoid mistakes in original manual operation and improve production efficiency.

8„ÄÅÈÄöËøáÂêÑÁéØËäÇÁöÑÁõëÊéßÂQåÂèØÁõëÊéßÂêÑÁîü‰∫߉Ωú‰∏öÁéØËäÇÂ∑•‰∫∫ÁöщΩú‰∏öÊ∞¥Â„^ÂèäËÉΩÂäõ„Äljÿì(f®¥)ÊèêÈ´ò‰∫ßÂìÅË¥®ÈáèÂêàÊݺÁéáËææÂàÓCøÉòqõÁöщΩúÁÄÇThrough the monitoring of each link, the working level and ability of workers in each production link can be monitored. In order to improve the qualified rate of product quality, it plays a role of promotion.

9„ÄʼnæùÊçÆÂ∏ÇÂú∫ÁªàÁ´ØÈîÄÂîÆÊï∞ÊçÆÁöÑælüËÆ°ÂQåÂè؉∫ÜËߣ‰∫ßÂìÅÂú®Â∏ÇÂúÞZ∏≠ÁöÑÊ¥ªÂä®ÊÉÖÂܵԺå‰∫ÜËߣÊ∂àË¥πËÄÖ‰ø°ÊÅØÔºå‰∏ÞZ∫åã∆°Ëê•Èîĉ∏éÂêéÊúüÂÆöÂà∂Êèê‰æõÊúÄÊúâÊïàÊúÄÂÆûÈôÖÁöÑÂàÜÊûêÂÜ≥Ω{ñ‰æùÊçÆ„ÄÇAccording to the statistics of market terminal sales data, we can understand the activities of products in the market and consumer information, providing the most effective and practical analysis and decision-making basis for secondary marketing and post - customization.