ŋUåčĄäļæšŊæšæŌ(guĻĐ)Ąäŧįŧ Tracing schemeåQ?/strong>

ŋUåæŊäļåæ°åĪĐåĪĐæäšĪéį䚧ååQčäŧäŧŽåæŊįĪūäž?xĻŽ)æåšįĄįåģåĻähæ°ïžæå―EåšĶäļéŦåQåŪđæäļå―åéŠãååį§åãäŧĨÆĄå åĨ―ãå·æĒå čĢ įéŪéĒæŊæŊįæŊãåĶä―čŪĐåæ·―ååŋŦæïL(fĻĨng)čūĻčŊ䚧åį䞊åQčŪĐäžäļæææ§åķæļ é―Hčī§åĒïžSeeds are products that deal with farmers every day, and they are the most basic working people in society. They are not well educated and easily deceived. There are many problems such as fake seeds, shoddy products and packaging. How can farmers simply and quickly identify the authenticity of products and enable enterprises to effectively control channel jumping?

ŋUåčĄäļįđåū Industry characteristicsåQ?br/>

ï?ãį§åäņåäh(huĻĒn)æ žåĐæķĶäļéŦïžčĶæąæŌ(guĻĐ)ĄææŽä―åŧåQæææäđ čįĻåQThe price and profit of seed products are not high, which requires low cost and durable effect.åQ?/span>

ï?ãäņååšåšåĻæ·åĪåQéĢåŌ(guĻĐ)ĨæïžįŊåĒæķåĢåQåŊđæŦ枎ägčŪÖĪčĶæąéŦãThe products are stored outdoors, exposed to the sun and the sun, and the environment is harsh, requiring high requirements for scanning hardware equipment.

åŊđäžäļįåĨ―åĪBenefits to enterprises

æéŦūlčĨåģįįå(qiĻĒng)æķæ?/span>

Improve the timeliness of business decision - making

åäžäļį―ĄįūpČŧæäūåŪæīåįĄŪįäņåæ°æŪïžōqķäŋčŊæ°æŪééįå?qiĻĒng)æķæ§ãįŧäžäļæäūäšå(qiĻĒng)æķåžŪįåģįäūæŪåQäÉäžäļč―åĪéĒåŊđįŽæŊäļåįæŋįįŦäšååšå(qiĻĒng)æķæĢžŪįūlčĨ―ĄįåģįåQååūįŦäšäžåŅProvide complete and accurate product data to the enterprise management system and ensure the timeliness of data collection. It provides enterprises with timely and accurate decision-making basis, enabling them to make timely and correct management decisions in the face of rapidly changing fierce competition and gain competitive advantages.

ååįéē―Hčī§Anti - channeling goods of commodities

ūléåį―Hčī§čĄäØ(fĻī)äž?xĻŽ)äļĨéåŠ?jiĻĢng)åæ?zhĻĻn)ĻįåļåšéåŪį§ĐåšïžéįĻååæ°ååįŪĄįįģŧūlååQäžäļįæŊäļäŧķååé―æģĻåäščínäŧ―į åQåģååįæ°ååä―ŋåūååå ähäšäļŠæ§åãäžäļåūU§įŪĄįähåïžåŊäŧĨåĐįĻåšåŪį?shĻī)čŊåįäŋĄå?qiĻĒng)čŪĄįŪæšį―ūlïžč―ĀLūåįĄŪįįæ§äņåįđéæ åĩåį䞊æ åĩãDealer's behavior of channeling goods will seriously affect your market sales order. After adopting the commodity digital management system, every commodity of the enterprise is registered with an identity code, that is, the digitalization of the commodity makes the commodity personalized. Managers at all levels of the enterprise can easily and accurately monitor the circulation and authenticity of products by using fixed phones, short messages and computer networks.

å åžšåŊđåļåšįæ§åķ―ĄįTo strengthen the control and management of the market

éčŋ䚧åéåŪäŋĄæŊééãåéĶïžåŪį°äšåŊđéåŪåįååšãåūU§įŪĄįïžäŋčŊäšåļåšåĨåšähåšå°ååąãč―ææįæ§åķåšååčī§åQåæķåŊđéåŪåįč·ítŠčŊäžÍžæåĐäšäžäļæĢžŪéæĐéåŪåä―äžäžß_(dĻĒ)žäŋčŋåļåšéåŪãThrough the collection and feedback of product sales information, the division and classification management of vendors are realized, and the healthy and orderly development of the market is guaranteed. It can effectively control regional delivery and track and evaluate vendors, which is helpful for enterprises to correctly select sales partners and promote market sales.

éåŪähåįįĢįŪĄįSales personnel supervision and management

éåŪähåäŧĨäžäļææģäļšåšžåQäŧĨ䚧åæ įūäŋĄæŊäļšæåŊÆDŋčĄéåŪæīŧåĻïžæéŦéåŪéäžį―Ąįæ°īåã^ã?/span>

Sales personnel conduct sales activities on the basis of enterprise ideas and under the guidance of product label information to improve the management level of the sales team.

ååäļĒåĪąåæĨūpČŧCommodity Loss Investigation System

å―ææđåååĻįäņåčŋčūéäļäļĒåĪąæčĒŦįïžååŊäŧĨåĻæŽįģŧūläļæåĪąååĪæĄïžå―čŊĨæđååčŋå ĨåļåøŋčĄååčínäŧ―æĨčŊĒæķåQįģŧūläž(xĻŽ)čŠåĻčŪ°å―įļå ģäŋĄæŊåQäžäļįŪĄįähåæ đæŪįģŧūläŋĄæŊå(qiĻĒng)æķåæķčīđč čūpŧïžqčĄq―čļŠč°æĨåQäūŋäšåŊŧæūčŊĨæđååã?span style="font-family: arial, helvetica, sans-serif; color: rgb(89, 89, 89);">When a batch of goods is lost or stolen during production and transportation, the loss can be reported and filed in the system. When the batch of goods enters the market to inquire about the identity of the goods, the system will automatically record relevant information, and enterprise management personnel will contact consumers in time according to the system information to conduct follow-up investigation so as to facilitate the search for the batch of goods.

åšå ĨåšįŪĄįå Ļ―Eæ°į įæ§Warehouse management

䚧ååšå Ĩåščŋ―EïžæķéĪåæĨäŧåĻ―{éĻéĻähåæå·Ĩįæ°æŪå―å Ĩãæ°æŪįŧčŪĄå·Ĩä―ïžæđäØ(fĻī)æĄį åčŪūåĪčŠåĻééïžåå°åĪ§éæå·ĨéåĪå·Ĩä―åQå―éŋähäļšåĪąčŊŊį°čąĄïžéä―äššåå·Ĩä―åžšåšĶã?/span>

In the process of entering and leaving the warehouse, the manual data entry and statistics work of personnel in the original warehouse and other departments is eliminated, and the automatic collection of bar code equipment is changed to reduce a large number of manual duplication of work, avoid human error and reduce the work intensity of personnel.

䚧éæ§åķOutput control

ūpČŧåŊäŧĨææå°æ§åķäļåąäžäļãååįįäņéãæŊōqīæ đæŪį䚧čŪĄåïžäļåįļåšæ°éįååčínäŧ―į ææ čŊïžåæķæäūæĨčŊĒæåĄãįäš§å°ąåŠč―ææåįæ°éįäņåQæēĄæåæģčķ éį䚧ãčŋæ ·åŊäŧĨéŋå ä―åĪåó@įŊïžéēčŋč§į䚧åčĄäļ―ĄįåĪąæ§ãThe system can effectively control the output of subordinate enterprises and brands. Each year, according to the production plan, a corresponding number of commodity identification codes or logos are issued and inquiry services are provided. Production can only be carried out according to the quantity issued, and there is no way to overproduce. This can avoid cardiopulmonary bypass, prevent illegal production and industry management from getting out of control.

æįŧåå䚧åđå ĨéåŪåļå?/strong>Stop fake products from entering the sales market

å?qiĻĒng)æķåį°äđÞp(chuĻĪng)įį°čąĄïžéēæĒåå䚧åđå ĨäžäļéåŪåļåšïžåĪ§åĪ§éŋå äšå æĪįŧäžäļåļĶæĨįįŧđäŧĨå?qiĻĒng)äŋĄčŠæåĪąãFound the phenomenon of random labeling in time to prevent fake products from flowing into the enterprise sales market, thus greatly avoiding the economic and reputation losses brought to the enterprise.

åŪį°äš§åčīĻéč·čļŠūpČŧįåŊq―æšŊæ?/strong>The traceability of product quality tracking system is realized

䚧åčīĻéæŊäžäļįįå―ãéčŋūpČŧå ĻéĒč·čļŠéé䚧åäŋĄæŊåQåŊäŧĨåŪįîCŧæūlįĻæ·å°äš§åįäņ―{įļå ģäŋĄæŊįq―æšŊåQäŧĨäūŋæį §æĄį æđÆĄåįļå ģäŋĄæŊqčĄūläļåŽååĪįåQåŪįîCņåčŋ―æšŊåč―ïžåļŪåĐäžäļå ĻéĒæéŦ䚧åčīĻéãProduct quality is the life of an enterprise. By comprehensively tracking and collecting product information through the system, the traceability of relevant information from end users to product production can be realized, so as to carry out unified recall processing according to bar code batches and relevant information, realize the product traceability function, and help enterprises comprehensively improve product quality.

äļåĄđįĻBusiness process

1ãæ đæŪäžäļį°įĶå

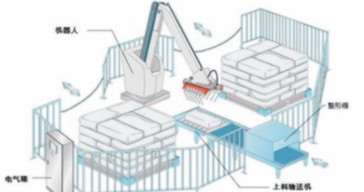

åŪčĄčŋ―æšŊį įįžū~According to the current situation of the enterprise, the first step is to compile the traceability code. Seed tracing toã?img src="/Upload/Img/2018/07-22/5b542ec49f40a.png" style="float: right;" title="ŋUåæšŊæš3.png"/>

2ãåĶææŊæå·Ĩå čĢ åQåģŪčŋ―æšŊį įĻæ ―{ÖÅåžč(chuĻĪng)å°åŊđåšäņåäļãIn the case of manual packaging, the traceability code will be affixed to the corresponding product in the form of a label.

3.åĶææŊčŠåĻįšŋįïžäžäļåŊéčŋįäņūUŋæđé å(qiĻĒng)įļåšææŊæDĩéįåîCņååūU§įķčĢ æå čĢ äļã?/span>If it is an automatic production line, the enterprise can attach to bottles or packages at all levels of the product through production line modification and corresponding technical means.

4.åŪį°įäņqįĻæ°æŪäļæšŊæšįžį įå åQåŪį°åŊéčŋæšŊæšū~į q―æšŊå°į䚧čŋ―EčŊĶūlčŪ°å―įåč―ã?/span> Realize the association between production process data and traceability code, and realize the function of tracing back to detailed records of production process through traceability code.

5.Ūå ģččŋįįžį å(qiĻĒng)įäņqįĻæ°æŪéčŋū|įŧäļäž čģäņåæšŊæšåã^åÍžå―ĒæåŪæīįå ĻđįĻq―æšŊä―įģŧã?/span>

Upload the associated coding and production process data to the product traceability platform through the network to form a complete whole-process traceability system.

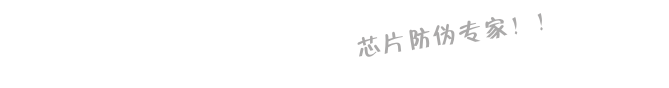

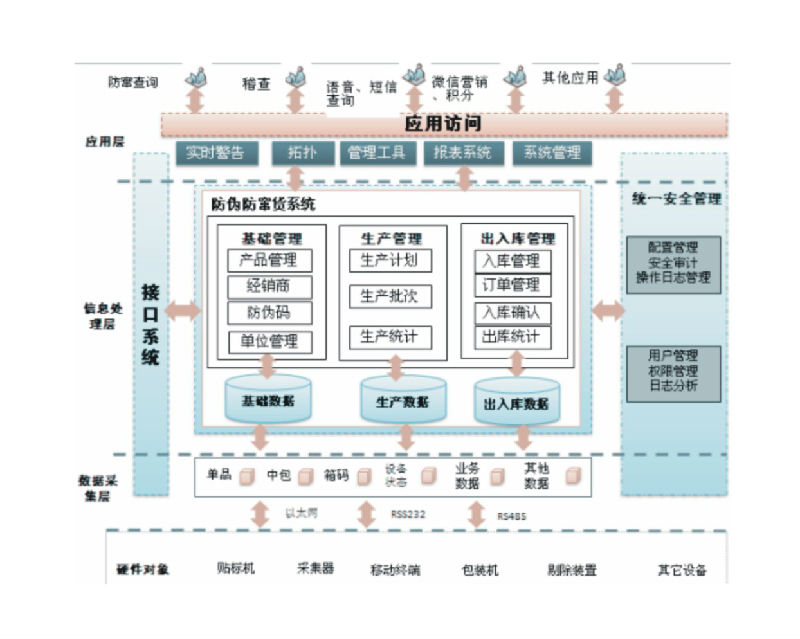

ūpČŧūlæsystem structure

ï?span style="font-family: arial, helvetica, sans-serif; color: rgb(89, 89, 89); font-size: 14px;">æ°æŪééåąData acquisition layer

æåšåąäļšæ°æŪééåąåQå°å čĢ æ°æŪäŧĨå(qiĻĒng)å å ģįģŧãåšžäŋĄæŊãåšå Ĩåšæ°æŪäž åæåĄå?/span>

The bottom layer is the data acquisition layer, which transmits the packaging data, the association relationship, the basic information and the inbound and outbound data back to the server

ï?strong>äŋĄæŊåĪįåąInformation processing layer

―WŽäšåąäØ(fĻī)æĨæķãįŪĄįãåæãææïžæååį§åšįĻæ°æŪãæĨčĄĻæ°æŪïžäūäžäļæĨåļļå·Ĩä―äÉį?/span>

The second layer is to receive, manage, analyze and mine all kinds of application data and report data successfully for the daily work of the enterprise

ï?strong>åäļåšįĻåąBusiness application layer

―WŽäļåąæäūįŽŽäļæđæ°æŪåŊŌ(guĻĐ)ĨãåĻæ°æŪäļåŋč·åæ°æŪäūäžäļåšįĻäšäš§åq―æšŊãéē䞊æĨčŊĒãéē―HæĨčŊĒãčĨéæĻåđŋ―{ãThe third layer provides third-party data docking, data acquisition in the data center for enterprises to apply in product traceability, anti-counterfeiting inquiry, anti-channeling inquiry, marketing promotion, etc.

ū|įŧéĻįÖvNetwork deployment

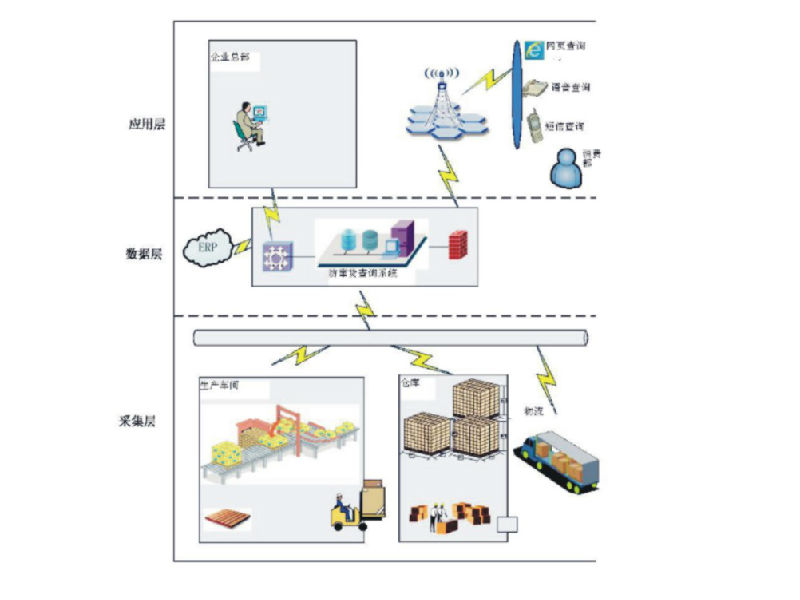

čŠåĻįäņAutomatic production

ūlåŪįäņäŋĄæŊ(æä―åãįšŋåũįūlįåQ?/span>

Binding production information ( operator, line number, team, etc. )

åïL(fĻĨng) æøĩį ?čĩäļ䚧ååŊäļâčínäŧ―čŊâį ãčŪ°å―æ°æŪãįŧåŪäžäļäŧĢį ãį䚧æĨæãå čĢ äŧĢį ãæŊæ§äŧĢį ãįŊäŋäŧĢį ãéæšį åQæä―åãįšŋåũįūlïž―{The code spraying machine assigns a unique " identity card" code to the product, records data, binding enterprise code, production date, packaging code, toxicity code, environmental protection code, random code ( operator, line number, team, etc. )

å čĢ Packing

1ã?span style="font-family: arial, helvetica, sans-serif; color: rgb(89, 89, 89); font-size: 14px;">äššå·ĨčĢ įŪąManual packingåQ?/span>

åĒå éĀLĄčĢ į―ŪåQåšåįŪąäļįŪąå äņåïžéēæĒčĢ é―ąïžčŠåĻįæōqķæå°įŪąæ ïžå―ĒæååäļįŪąįå ģčïžäššå·Ĩčīīæ ōqķæåšåščĢ įŪąåQAdd blocking device to distinguish the box from the products in the box to prevent the wrong box from being loaded. Automatically generate and print box labels to form the association between single items and boxes; Manual labeling and packing in sequence;

2ã?span style="font-family: arial, helvetica, sans-serif; color: rgb(89, 89, 89); font-size: 14px;">čŠåĻčĢ įŪąAutomatic packingåQ?/span>

æĒæķæå°―ąæ æđåžåQįģŧūlč·åčĢ ―ąæšäŋĄå·åQææ Ō(guĻĐ)ŪæŊäūåQæå°įŪąæ ïžäššå·Ĩæåšæ 饚åšč(chuĻĪng)åĻįŪąåäļåQOn - the - spot box label printing mode: the system obtains the signal of the box loader ( or prints the box label according to the proportion ) and manually pastes it on the box according to the label order;

čŠåĻčīīæ æđåžAutomatic labeling methodåQ?/span>

čĢ įŪąåŪæåïžčŠåĻčīīæ æøŠåĻčĩį ïžåšåŪåžæŦæåĻæŦæ―ąæ ōqķåÅæâåå?―ąâå ģčïž

After packing, the automatic labeling machine will automatically assign codes, and the fixed scanner will scan the box labels and form a " single item - box" association.

į åstack

1ãähå·Ĩį åæđåžManual stacking methodåQ?/span>

äššå·ĨŪįŪąåå å åĻæįäļïžæ Ō(guĻĐ)Ūâåå?―ąâæŊäūčŪūåŪåÆDūūå°æįå å æ°éæķčŠåĻæå°åæ æįæčæåį ?/span>

Manually stack boxes on pallets, and automatically print stack marks or generate virtual stack codes when the set value of " single item - box" ratio reaches the number of pallets stacked.

2ã?span style="font-family: arial, helvetica, sans-serif; color: rgb(89, 89, 89); font-size: 14px;">čŠåĻį åæđåžAutomatic stacking modeåQ?/span>

į åååŪčĢ äļäļŠåšåŪæŦæåĻčŊÕd―ąæ åQį åæščŠåĻį ååQåį įįæåŊæ đæŪæŊäūæč į åæšåŪæäŋĄå·åQ?/span>

Before stacking, a fixed scanner is installed to read the box label, and the stacker automatically stacks, and the stacking code can be generated according to the proportion or the stacker completion signal.

ä―äļđįĻ work flow

å Ĩåšbe put in storage

1ãį䚧å ĨåšæđåžProduction and warehousing methodsåQ?/span>

įäņåčŠåĻå Ĩåšïžæ éäššå·Ĩæä―

Automatic warehousing after production without manual operation

2ãæŦæå ĨåšæđåžScanning and warehousing methodsåQ?/span>

æŧĄåįæŦäļ―ąåŊæīåå ĨåšåQäļæŧĄäļåįéįŪąæŦæå Ĩåš 1ãįŧåŪäņåäŋĄæ?/span>

A full stack of swept boxes can be put into storage in the whole stack, while less than one stack can be scanned and put into storage one by one, binding product information

3ãįŧåŪįĐđäŋĄæŊBinding Logistics Information

4ãįŧåŪįŧéåBinding Dealers

5ãåčī§æ°éįŧčŪ?Statistics of Shipment Quantity

åšåšdelivery of cargo from storage

―WŽäļæĨStep 1åQ?/span>

äŧåĻéĻåķä―åšåšååQįŧåŪįŧéåãįĐđäŋĄæŊãäņåäŋĄæŊãåčī§æ°éïžæŊæäļååĪ䚧åæķåčī§ïž

Warehousing Department makes issue documents, binding dealers, logistics information, product information and shipment quantity ( supports shipment when there is more than one product )

―WŽäšæĨStep 2åQ?/span>

åčī§åäÉįĻPDAæŦææŠäļč――åšåšååQåÆæįŪą/åæŦæïžčūÖ°åčī§æ°éæķčŠåĻæ―Cšïž

The consignor downloads the issue document with PDA scanning gun and scans it by box / stack to automatically prompt when the delivery quantity is reached.

―WŽäļæĨStep 3åQ?/span>

äļäž åčī§æ°æŪUpload shipment dataåQ?/span>

åQåšåšįģŧūlæŊææ ūUŋį―ūlæä―ïžæä――åïžåŋŦéåčī§ïžåå°äššå·Ĩæä―åQ?/span>

( Outbound system supports wireless network operation, easy operation, fast delivery and less manual operation )

q―æšŊį Tracing code

įķį æå į Bottle code or package codeåQ?/strong>

åŊäļíwŦäūį ?æ°åį ãæĄį ãäšūlīį åQåŊįŨžäļåģåŪ?åQ?/span>

unique identity code ( digital code, bar code, two-dimensional code, which can be determined by the enterprise );

äūåĶFor exampleåQ?/span>

X0001 4241 0 1 2 00000000001åQ?/span>

č§åRulesåQäžäļäŧĢį ïž5ä―ïž+įäņæĨæåQ?ä―ïž+å čĢ äŧĢį åQ?ä―ïž+æŊæ§äŧĢį ïž1ä―ïž+įŊäŋäŧĢį åQ?ä―ïž+éæšį ïž12ä―ïžãïžäŧ äūåčïžåŊåč°æīåQïž

enterprise code ( 5 bits ) + production date ( 4 bits ) + packaging code ( 1 bit ) + toxicity code ( 1 bit ) + environmental protection code ( 1 bit ) + random code ( 12 bits ). ( for reference only, can be adjusted );

ïëŪąį Box codeåQ?/span>

åÏxķæå°čīīæ æč å·į æšå·å°―Þq åQ?/span>

immediate printing of labels or printing of box codes by a printer

äūåĶFor exampleåQ?/span>

X0001 4241 0 1 2 000000000001åQ?/span>

č§åRulesåQ?/span>

äžäļäŧĢį åQ?ä―ïž+įäņæĨæåQ?ä―ïž+å čĢ äŧĢį åQ?ä―ïž+æŊæ§äŧĢį ïž1ä―ïž+įŊäŋäŧĢį åQ?ä―ïž+éæšį ïž12ä―ïžãïžäŧ äūåčïžåŊåč°æīåQïž

enterprise code ( 5 bits ) + production date ( 4 bits ) + packaging code ( 1 bit ) + toxicity code ( 1 bit ) + environmental protection code ( 1 bit ) + random code ( 12 bits ). ( for reference only, can be adjusted );

č·šį Stamping codeåQ?/strong>

åÏxķæå°åį åQäđåŊčæč·šåQæ éæå°æ įūåQäØ(fĻī)äžäļčįææŽã?/span>

printing stack code immediately; It can also be stamped virtually without printing labels, thus saving the cost for the enterprise.

äūåĶFor exampleåQ?/span>

X0001 4241 0 1 2 000000000001åQ?/span>

č§åRulesåQ?/span>

äžäļäŧĢį åQ?ä―ïž+įäņæĨæåQ?ä―ïž+å čĢ äŧĢį åQ?ä―ïž+æŊæ§äŧĢį ïž1ä―ïž+įŊäŋäŧĢį åQ?ä―ïž+éæšį ïž12ä―ïžåQäŧ äūåčïžåŊåč°æīåQenterprise code ( 5 digits ) + production date ( 4 digits ) + packaging code ( 1 digit ) + toxicity code ( 1 digit ) + environmental protection code ( 1 digit ) + random code ( 12 digits ) ( for reference only and can be adjusted )

ūpČŧåšįĻSystem application

1ãäņåčŋ―ítŠïž(xĻŽ)ūpČŧåå°æĨčŊĒ,

Product tracking: system background query

2ãéē―HæĨčŊĒïž(xĻŽ)ūpČŧåå°æĨčŊĒãäļįĻïž―E―æĨåŪïž―E―æĨåQåŊéïž

Anti - channeling inquiry: system background inquiry, special ( inspection treasure ) inspection ( optional )

3ãéē䞊æĨčŊĒïžåŊéïžåQäļå―åčŊåŪå Ļčŋ―æšŊåã^å°ãåūŪäŋĄãįäŋĄãčŊéëææ?

Anti - counterfeiting inquiry ( optional ): China Pesticide Safety Traceability Platform, WeChat, SMS, Voice, Mobile Phone,

4ãčĨéåšįĻåQåŊéïžåQį§Ŋåãįĩ(shĻī)åãåūŪäŋĄæĻōq?/span>

Marketing application ( optional ): points, e-commerce and WeChat promotion

ūpČŧåč―System function

1ãéē䞊Anti - counterfeitingåQ?/span>

æŊäļäļŠäšūlīį é―æŊåŊäļįïžåŦähæ æģåĪåķåQ?/span>

:Each two-dimensional code is unique and cannot be copied by others;

2ãäž(xĻŽ)åį§ŊåMembership PointsåQ?/span>

æķčīđč æŦæäņåäšūlīį åQææšå·æģĻåūlåŪåQæŊæŦäļäļŠį åūå°įļåšŋUŊååQäžäļåŊčŠå·ąåŪäđŋUŊåč§åã?nbsp;Consumers scan product two-dimensional codes, mobile phone numbers are registered and bound, each code is scanned to get corresponding points, and enterprises can define their own points rules.

3ãįŧéåææšæŦæåšåšïž(xĻŽ)ūléåæģĻåįģčŊŊĖåøPžéčŋæŦæ䚧åæįŪąäļįäšįŧīį ïžqčĄåčī§åQäžäļå éĻéčŋåå°åūå°įļåšæ°æŪåQįĨéįŧéåæŊåĶįŠčī§å(qiĻĒng)䚧åéåŪæ åüc(diĻĢn)?/span>

The dealer's mobile phone scans and issues the goods: the dealer applies for account registration and issues the goods by scanning the two-dimensional code on the product or box; The enterprise obtains the corresponding data through the background to know whether the dealer has jumped the goods and sold the products